Computerized Membrane Filter Press Operation Process

페이지 정보

본문

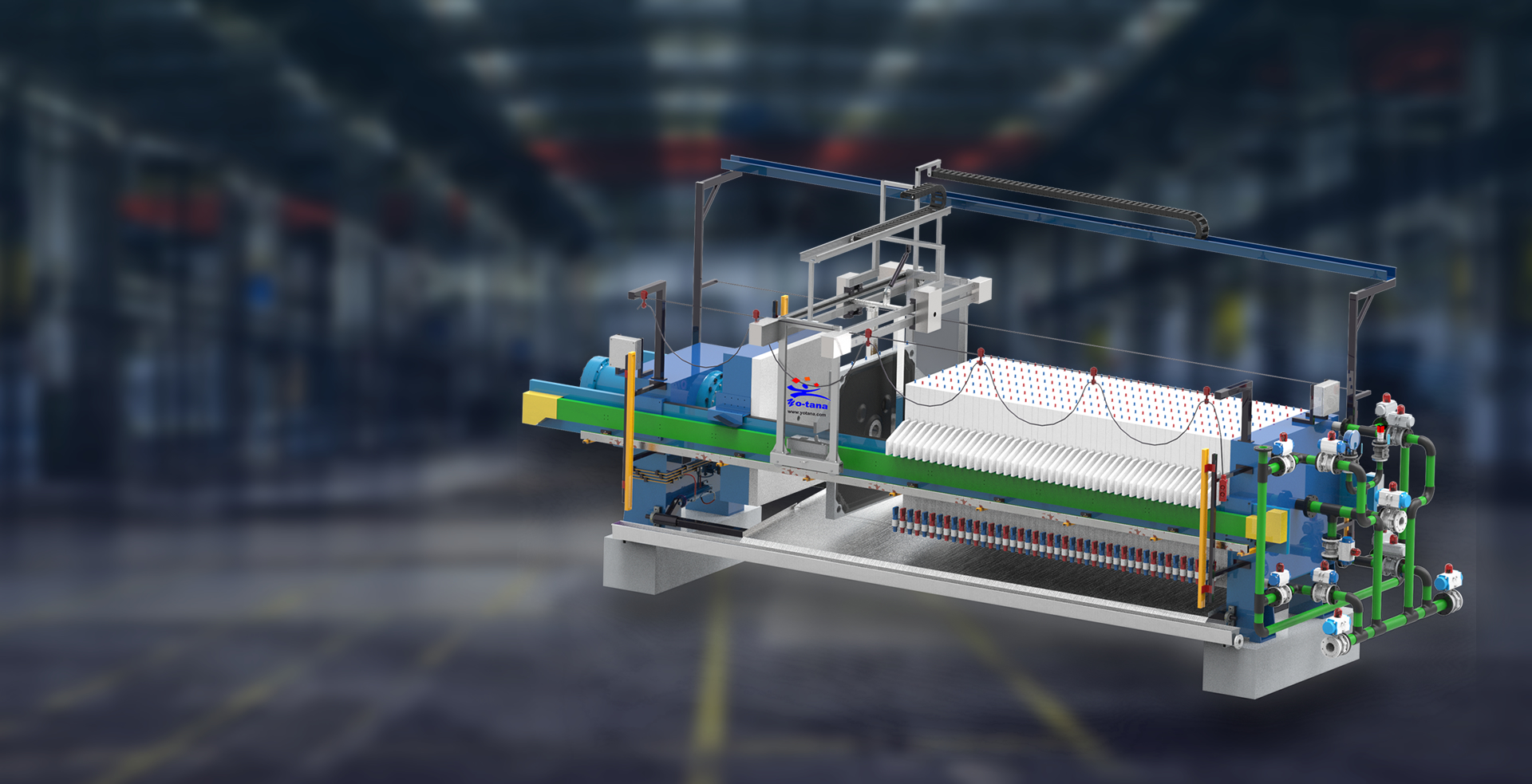

Change on the ability, press the pressurized button in the electric control cabinet. Consideration: Before pressing the filter plates, check the variety of the filter plates to ensure that the quantity meets your filtering requirement, and there shall not be any overseas matter caught between the sealing surfaces of filter plates. When it reaches the specified stress, pressurization stops automatically and holds the strain. Stress value is set by the feeding strain at the location, and no leaking is perfect, pay attention that the pressure should not be too high. Examine the on/off state of every pipeline valve as comes into pressure holding. Start the feeding pump slowly after affirmation, and the slurry flows into each filter chamber by means of the feeding port on the thrust plate.

Perry is one of the biggest sellers of used chemical industry tools. We've been shopping for and promoting used chemical processing plant and equipment for over 80 years. Our UK site has a 20,000 sq ft warehouse where we keep our stock of used chemical machines, making them instantly out there for re-sale into the chemical and related industries. Our inventory of used chemical tools contains: boilers, centrifuges, dryers, evaporators, glass lined tools, heat exchangers, mills, mixers, pumps, reactors, tanks, and lots of extra. A few of our gadgets may be unused or refurbished, and all items can be found for prior inspection. Steady mixers are sometimes used for prime production rates, mixtures of multiple process streams, or to eradicate batch-to-batch variations. Each of the forms of mixers in this text covers basic information, equipment design, utilization examples, and advantages/disadvantages. Kneaders are excessive-intensity mixers for cohesive strong techniques. Cohesives can be thought of as "sticky" materials, like adhesives or rubber. Some kneaders obtain their mixing action by squashing the mass flat, folding it, and squashing it once more. Additionally, the recessed chamber design allows for the next filter cake capability, resulting in longer operating cycles and lowered upkeep prices. HOW DOES A RECESSED CHAMBER FILTER PRESS WORK? A recessed chamber filter press works in an analogous solution to a plate and frame filter press, but with some variations in the design.

The extent of automation process control allows for process optimization past what is possible with strictly guide control. This overview describes kinds of manufacturing processes and various kinds of management schemes, from controls of individual units to Distributed Control Systems (DCS) that management a complete plant. Numerous forms of process management exist in the chemical industry. Extra easy processes may implement extra primary types of control such as suggestions or PI management, while massive, advanced plants might integrate hundreds or 1000's of management methods right into a distributed management system. The principle advantages of plate and body presses are the power to swiftly change filter cloths and employ a wider selection of filtration medium materials, including paper, which is incessantly used for superb filtration purposes. Filter paper, for example, could also be required in a course of where fast particle retention is essential, as wonderful particulates would either blind off the filter cloth or cross via it. Thus, free entry to the plate package is ensured from the facet. The product vary of ANDRITZ overhead filter presses includes chamber and membrane filter press machine for oil presses as much as a measurement of two,500 x 2,500 mm and an area of 2,000 m². The filtration pressures range from 7 to 30 bar.

A particular feature of this filter plate is the direct embedding of the filter membrane or cloth into the plate’s physique. Sometimes, advanced sealing know-how is employed to secure a firm attachment between the filter cloth and the filter plate, thereby stopping any leakage and misalignment of the filter materials. The filter plate options two grooves, one on the inside and another on the surface. Other components are the same as the common filter press: Control Panel(HMI), Hydraulic Cylinder and Hydraulic station, Beam, and Drip tray. The diaphragm filter press consists of a diaphragm plate and a standard plate arranged alternately. For the initial filtration cycle, sludge or slurry is pumped into the chamber, and the solids are collected on the filter cloth to form a filter cake. Inflation of the membrane: After the initial filtration cycle is completed, the membranes in the filter plates will probably be inflated by air or high-stress water. Half 6 of the seven-part collection on material choice for chemical process equipment focuses on choice/evaluation concerns, together with, and along with, materials compatibility for particular process chemistries. Overview supplied an inventory of surface finishing chemical process equipment and methods that sometimes need material choice for various ranges of exposure to process chemistries.

- 이전글Could The Industry Use Some Innovation? 25.03.07

- 다음글Is Smokeless Tobacco Safer Than Cigarettes? 25.03.07

댓글목록

등록된 댓글이 없습니다.